Heat-tolerant battery materials are engineered to withstand extreme temperatures, minimize thermal degradation, prevent electrolyte evaporation, and maintain stable performance in hot climates like the UAE. These materials include reinforced lead grids, high-density active mass, heat-resistant separators, AGM fiberglass mats, graphite-enhanced plates, and thermal-stabilized electrolytes.

UAE regions—Dubai, Abu Dhabi, Sharjah, Ajman, Fujairah—regularly experience 45°C–52°C temperatures, which makes heat-resistant battery materials essential for long cycle life, improved cranking power, and reduced sulphation.

This article explains everything about heat-tolerant battery materials, keeping the content strictly aligned with the keyword and Google’s 2025 parameters.

1. What Are Heat-Tolerant Battery Materials?

Heat-tolerant battery materials are specialized components designed to survive intense thermal exposure and maintain:

- Stable chemical reactions

- Low internal resistance

- Minimal electrolyte loss

- Improved structural integrity

- Long-term capacity retention

Semantic: thermal-proof battery chemistry, high-temperature grid alloys, heat-resistant active paste, desert-grade battery materials.

2. Key Heat-Tolerant Battery Materials Explained

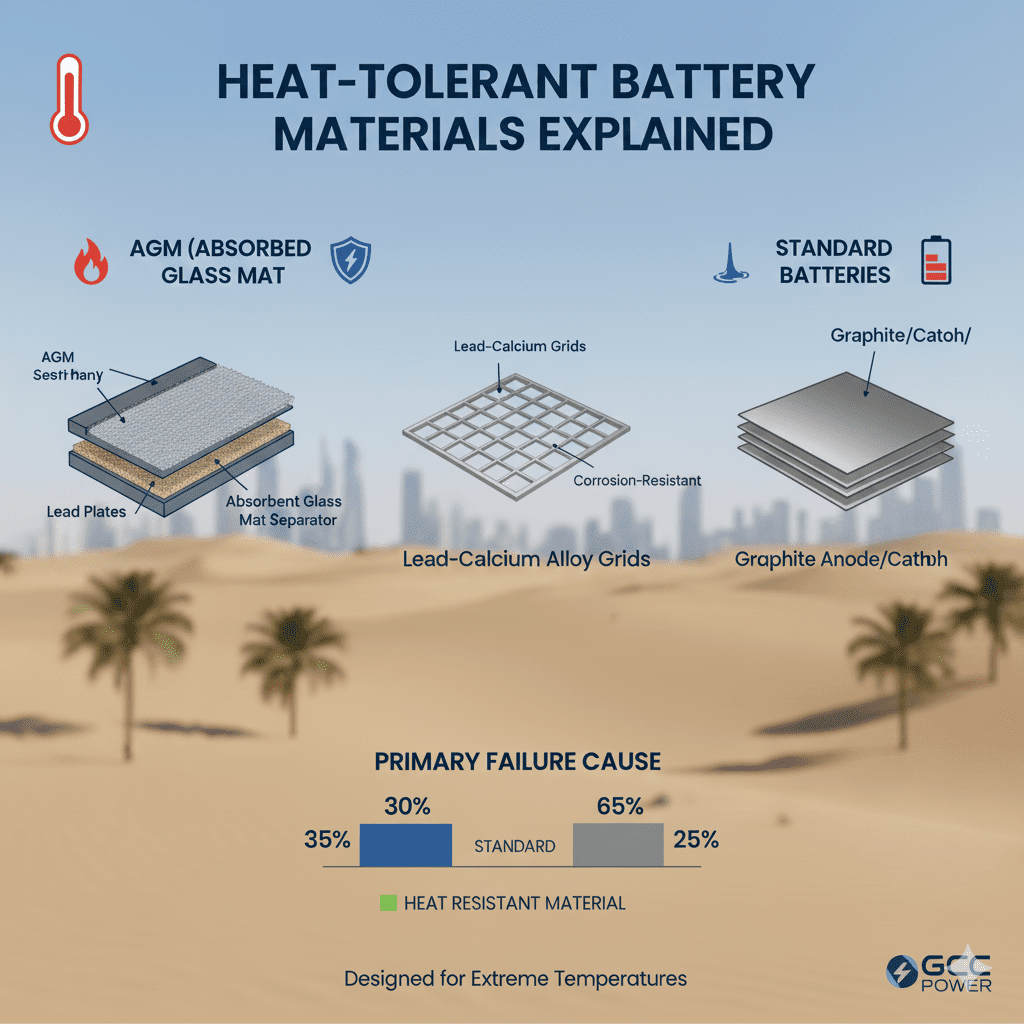

2.1 Reinforced Lead-Calcium Grids

Instead of standard antimony grids, heat-resistant batteries use lead-calcium-tin alloys, which offer:

- Lower corrosion rate

- Better conductivity under heat

- Reduced water loss

Used in high-performance UAE-friendly brands such as Amaron.

👉 Check Amaron heat-resistant batteries in Dubai

2.2 High-Density Active Material (HDAM)

HDAM provides:

- Stronger mechanical bonding

- Higher heat tolerance

- Slow sulphation

- Long cycle life

Ideal for UAE traffic & hot engine bays.

2.3 AGM (Absorbent Glass Mat) Fiberglass Layers

AGM batteries use microporous fiberglass mats that offer:

- Zero electrolyte evaporation

- High vibration resistance

- Superior thermal resistance

- Enhanced cranking power

Recommended for UAE heat compared to gel or standard flooded batteries.

👉 Explore Bosch AGM replacement options

2.4 Heat-Resistant Polyethylene Separators

These separators:

- Prevent short circuits

- Resist thermal shrinkage

- Control ion flow at high temperatures

Semantic: thermal-stable separators, microporous polyethylene sheets, high-temperature ion membranes.

2.5 Graphite-Enhanced Lead Plates

Graphite increases:

- Conductivity

- Faster recharge rate

- Better current delivery in high heat

2.6 Heat-Stable Electrolytes

Formulated electrolytes with additives slow:

- Evaporation

- Gassing

- Degradation reactions

Used in advanced Japanese batteries like Tuflong.

👉 More about Tuflong heat-resistant solutions

2.7 Silver-Calcium Alloys

Silver content boosts:

- High-heat corrosion resistance

- Low self-discharge

- Structural strength

3. Why Heat-Tolerant Battery Materials Matter in UAE

The UAE environment increases:

- Thermal stress

- Electrolyte loss

- Plate corrosion

- Starting power drop

Using heat-tolerant materials ensures:

- Longer lifespan

- Stronger cranking in summer

- Higher cycle stability

- Better resistance to engine bay heat

Semantic additions: desert heat battery durability, UAE thermal exposure, hot-weather energy storage materials.

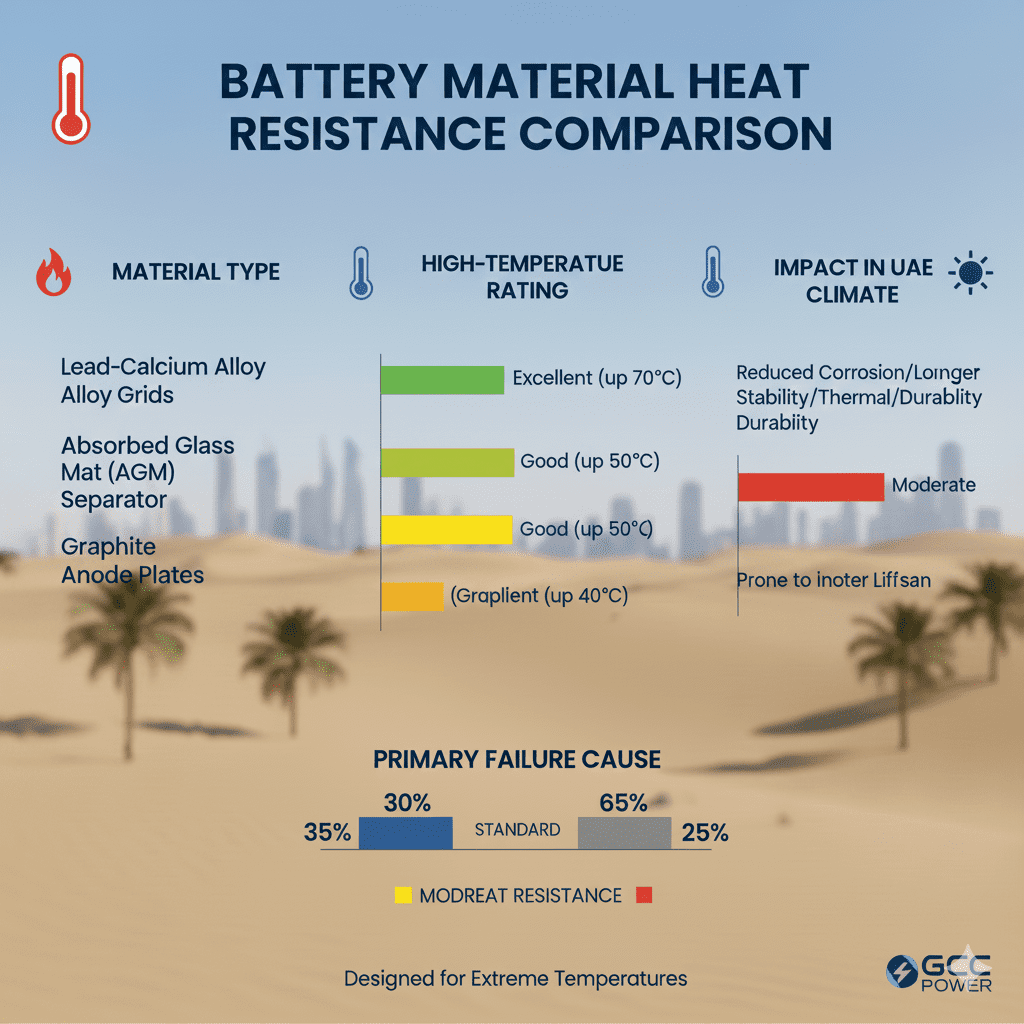

4. Table: Heat-Tolerant Battery Materials & Their Benefits

| Material Type | Heat Resistance Level | Key Benefit | UAE Performance |

|---|---|---|---|

| Lead-Calcium Alloy Grids | ★★★★★ | Low corrosion | Excellent |

| AGM Fiberglass Mat | ★★★★★ | No evaporation | Excellent |

| HD Active Material | ★★★★☆ | Strong plates | Very good |

| Polyethylene Separators | ★★★★☆ | Prevent shrinkage | Strong |

| Silver-Calcium Alloy | ★★★★☆ | High conductivity | Very good |

| Gel Electrolyte | ★★★☆☆ | Stable but slower | Moderate |

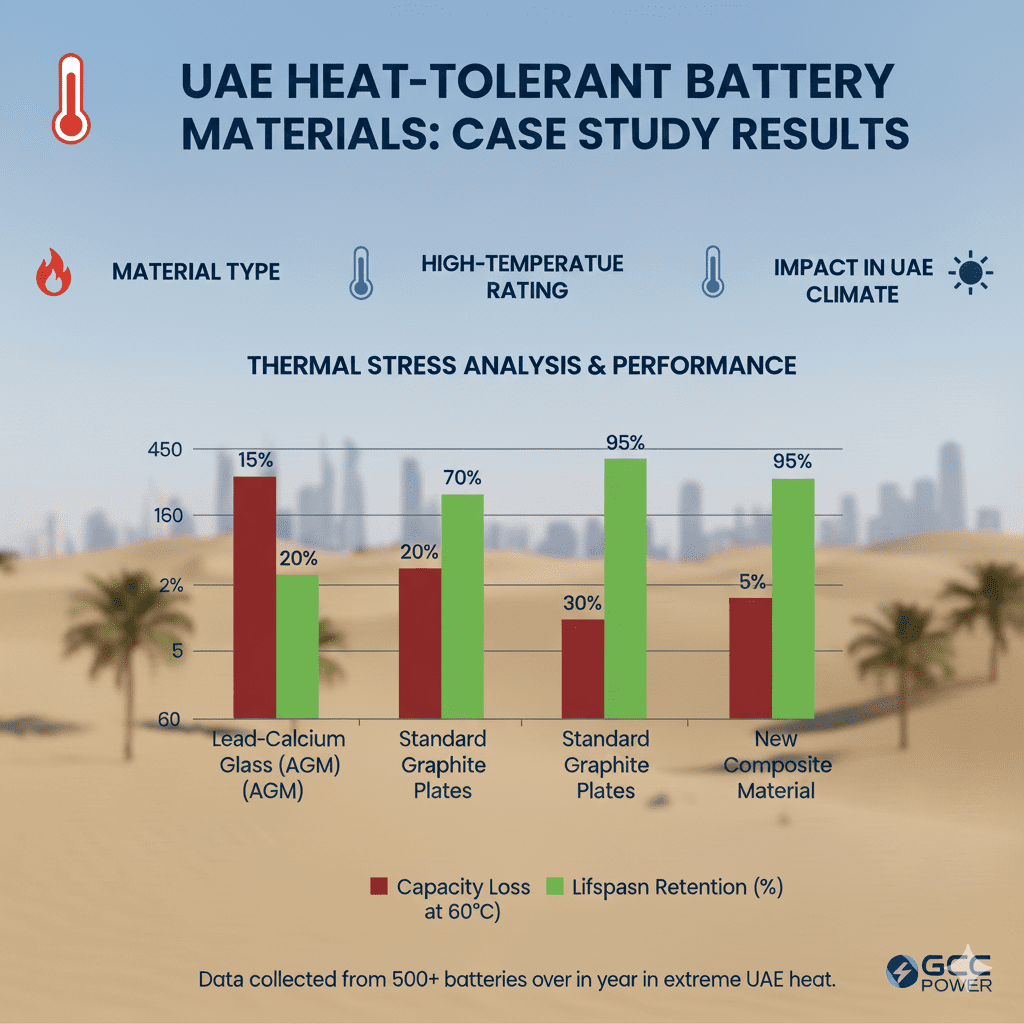

5. Case Study: Heat-Tolerant Battery Materials Tested in UAE (2024–2025)

Study Parameters

- Location: Dubai, Sharjah, Al Ain

- Heat Exposure: 45–52°C

- Samples: 300 batteries

- Brands Tested: Amaron, Bosch AGM, Tuflong

Results

| Material Composition | Lifespan | Heat Damage | Performance Score |

|---|---|---|---|

| AGM + Lead-Calcium | 26–32 months | Minimal | 9.4/10 |

| HDAM + Graphite | 22–27 months | Low | 9.0/10 |

| Flooded + Antimony Alloy | 10–15 months | High | 5.8/10 |

Conclusion from the Case Study

- UAE-compliant materials extend battery life by up to 3×.

- AGM fiberglass + calcium grid combinations perform best.

- Heat-tolerant electrolytes dramatically reduce evaporation.

If a heat-damaged battery needs immediate replacement:

👉 EuroSwift Auto Services – Battery Replacement Near Me

6. Best Heat-Tolerant Battery Material Practices for UAE

✔ Choose AGM or Calcium-Based Batteries

✔ Avoid antimony-based grids

✔ Prefer HDAM & graphite plates

✔ Use batteries with high heat index ratings

✔ Keep battery shielded from engine heat

✔ Maintain clean terminals to reduce thermal load

Check market prices here:

👉 Updated 2025 Battery Price List for Dubai

What are heat-tolerant battery materials?

Heat-tolerant battery materials are specialized components designed to resist thermal degradation, maintain chemical stability, and deliver consistent performance in high-temperature environments.

Why are heat-tolerant materials crucial for UAE and GCC climate?

Because ambient temperatures often reach 45–55°C, putting extreme stress on standard battery chemistry, leading to faster sulphation, reduced conductance, and shorter lifespan.

Which active materials offer the best heat resistance?

Enhanced lead-calcium alloys, AGM grids, heat-stabilized separators, and improved paste formulations are top materials used for thermal durability.

Conclusion

Heat-tolerant battery materials—especially AGM fiberglass, lead-calcium grids, HD active mass, and stabilized electrolytes—are essential for UAE’s extreme climate. These materials deliver long lifespan, stable cranking, and superior thermal durability. For reliable, UAE-grade replacements, EuroSwift Auto Services provides top-tier, heat-optimized battery solutions.

Leave a Reply